Description

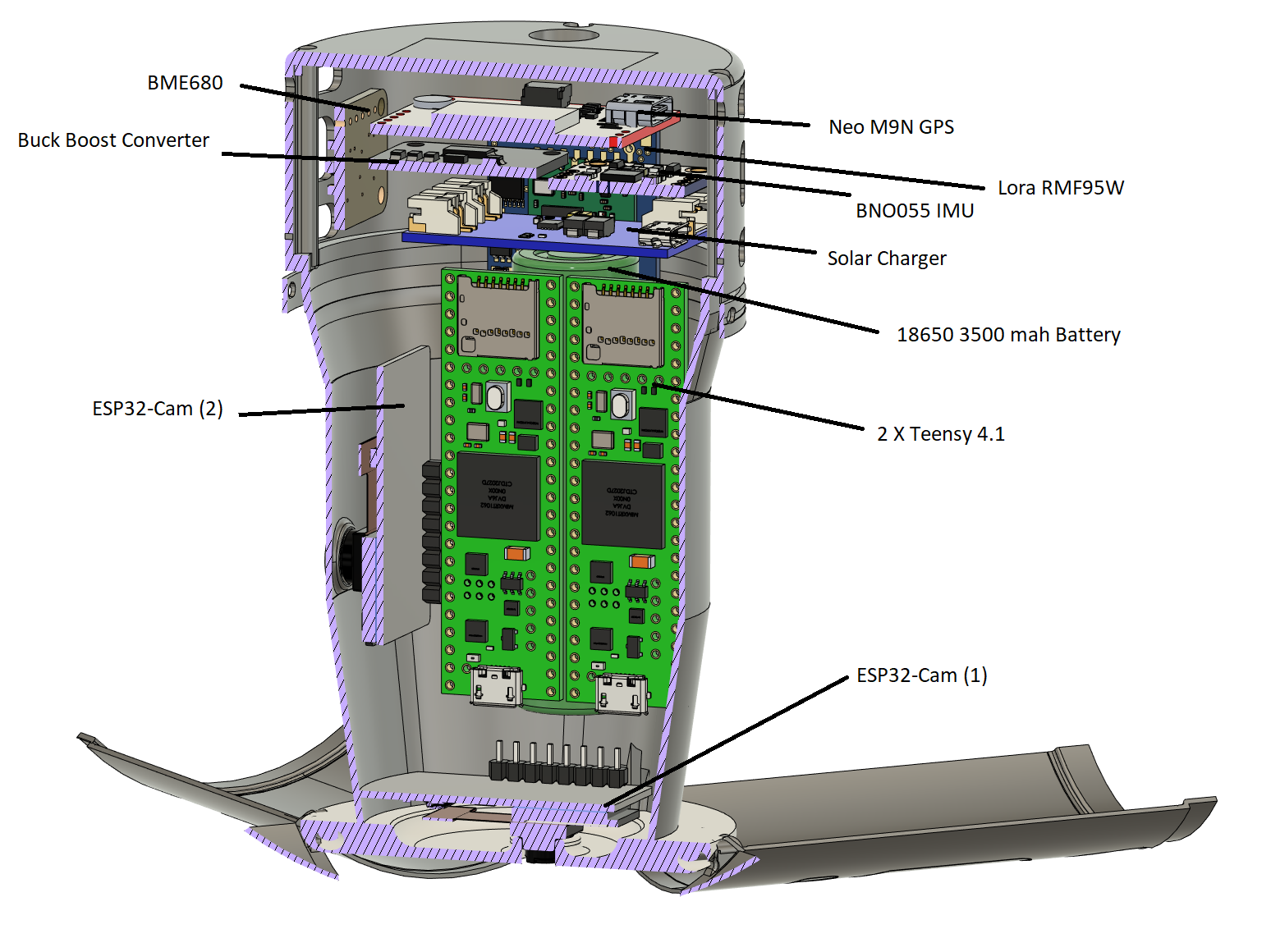

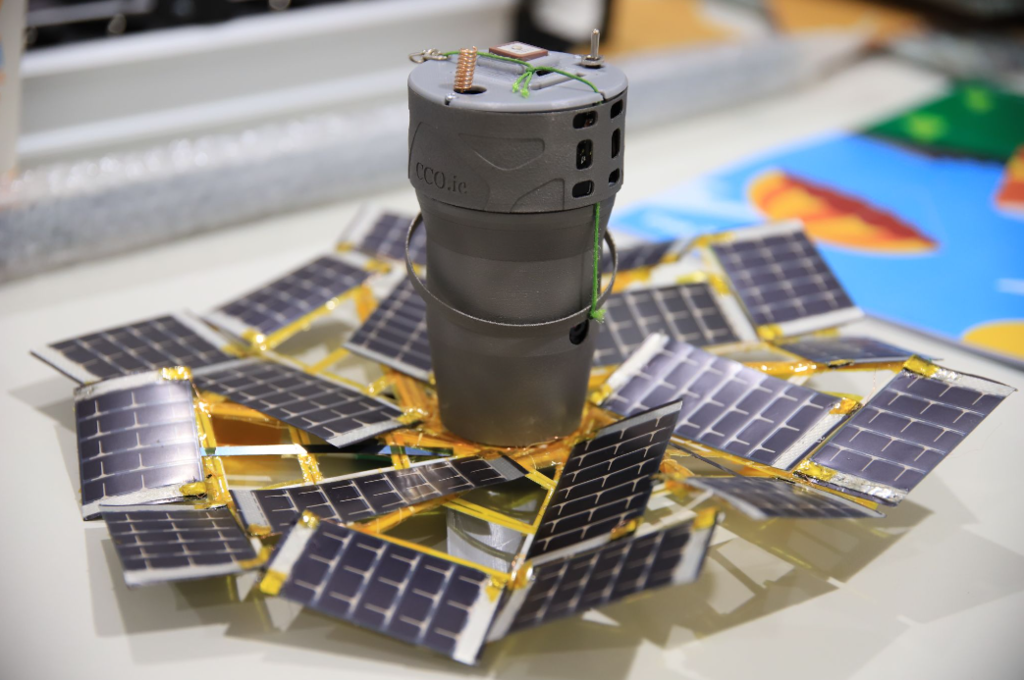

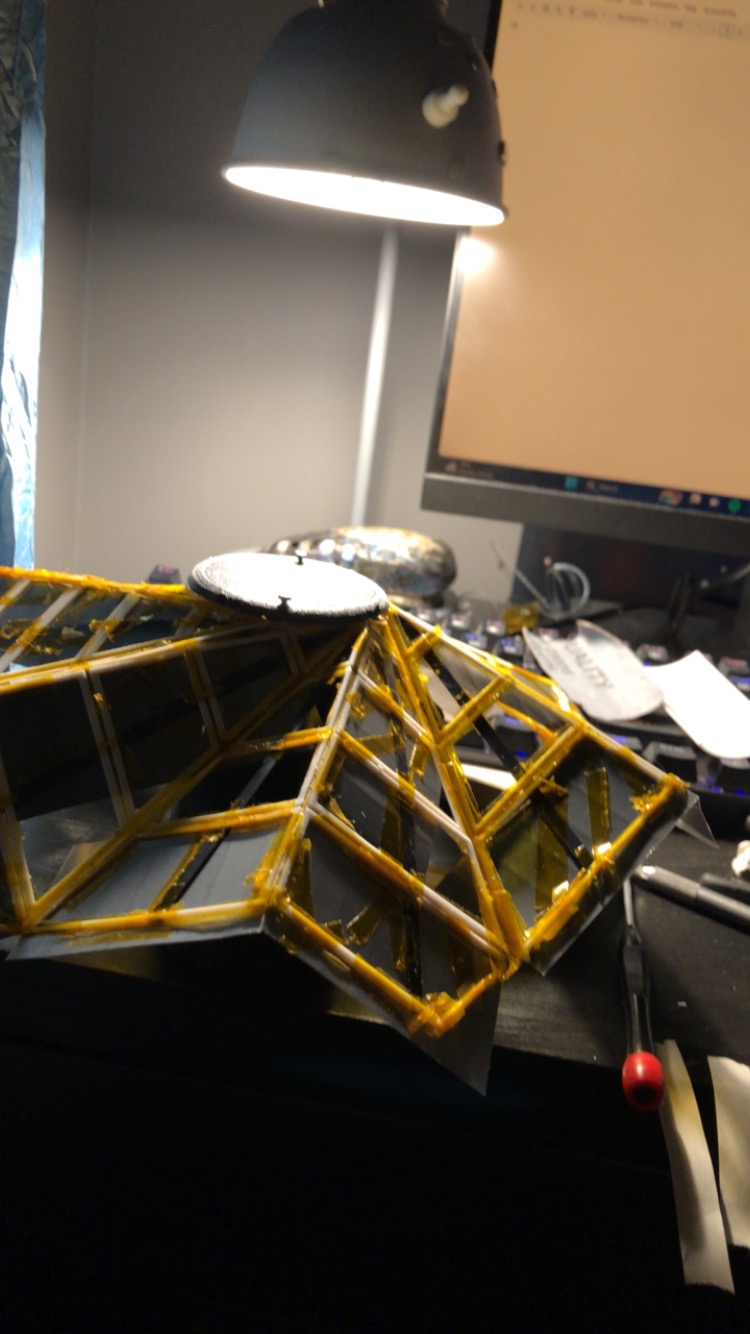

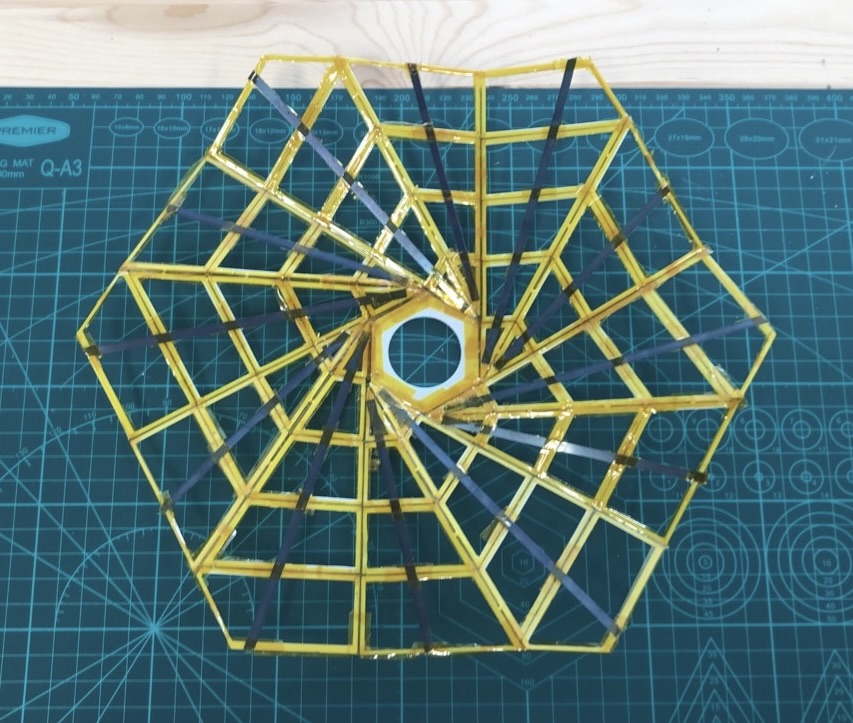

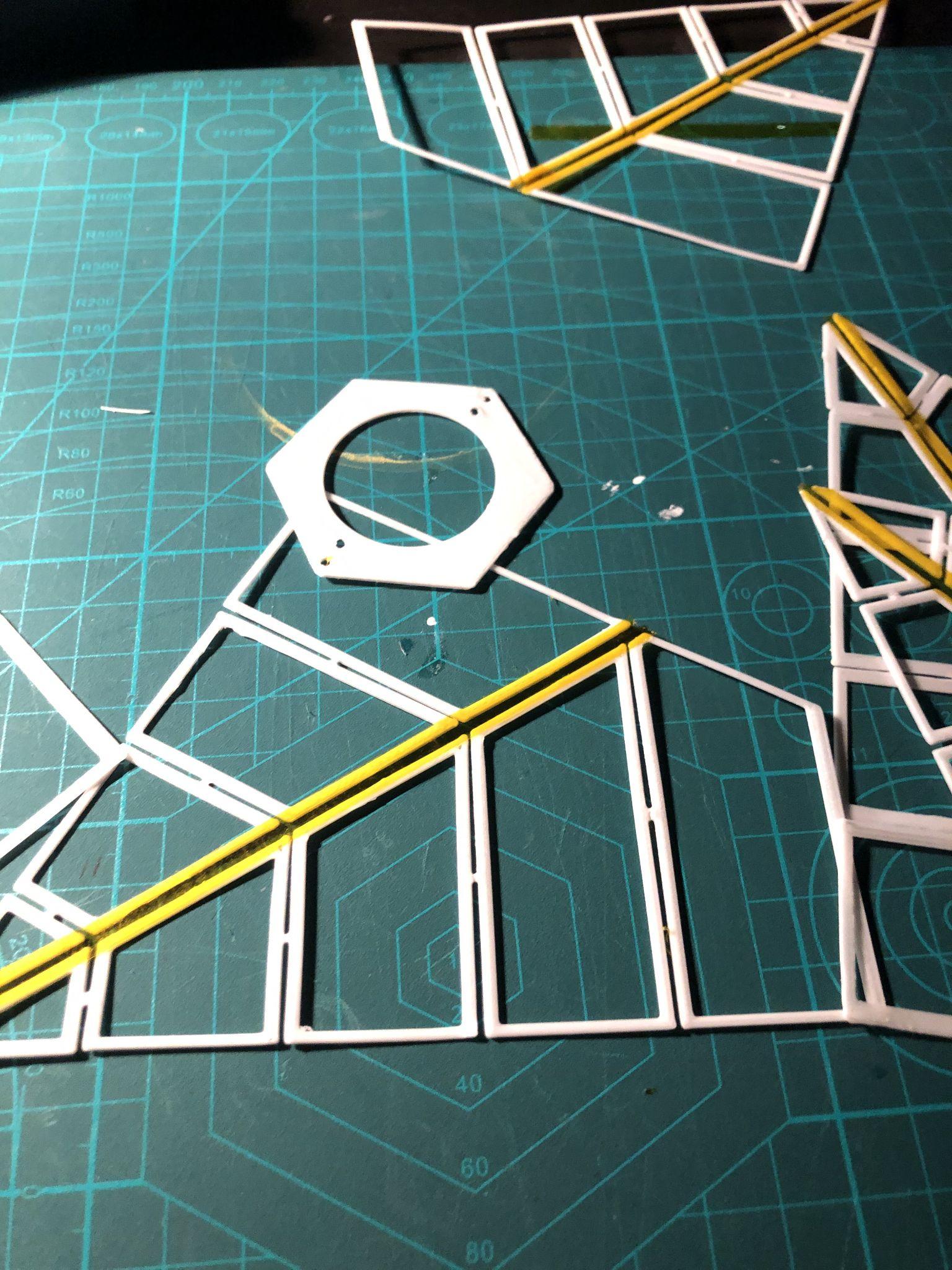

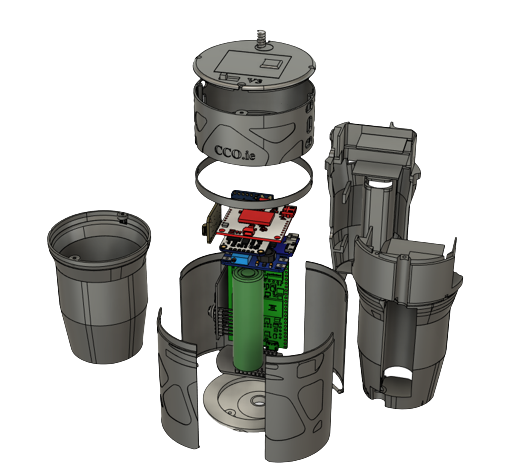

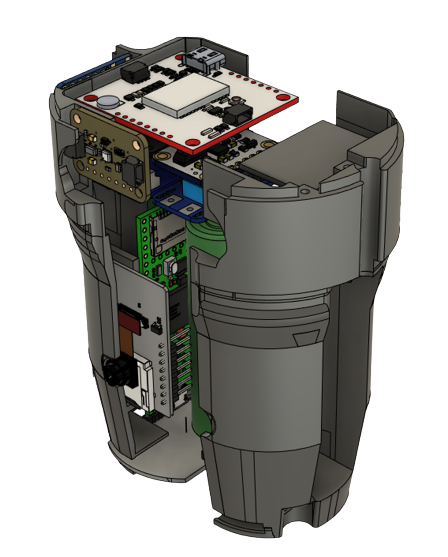

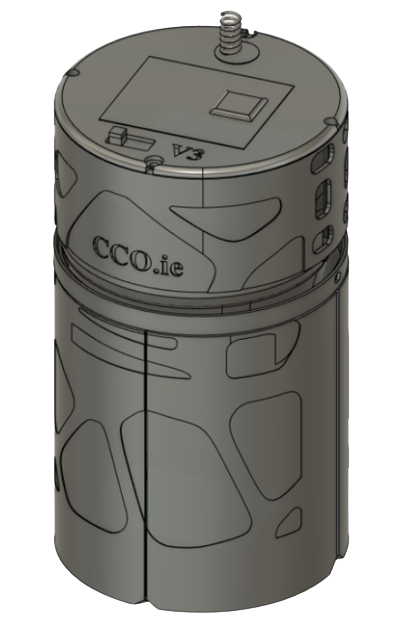

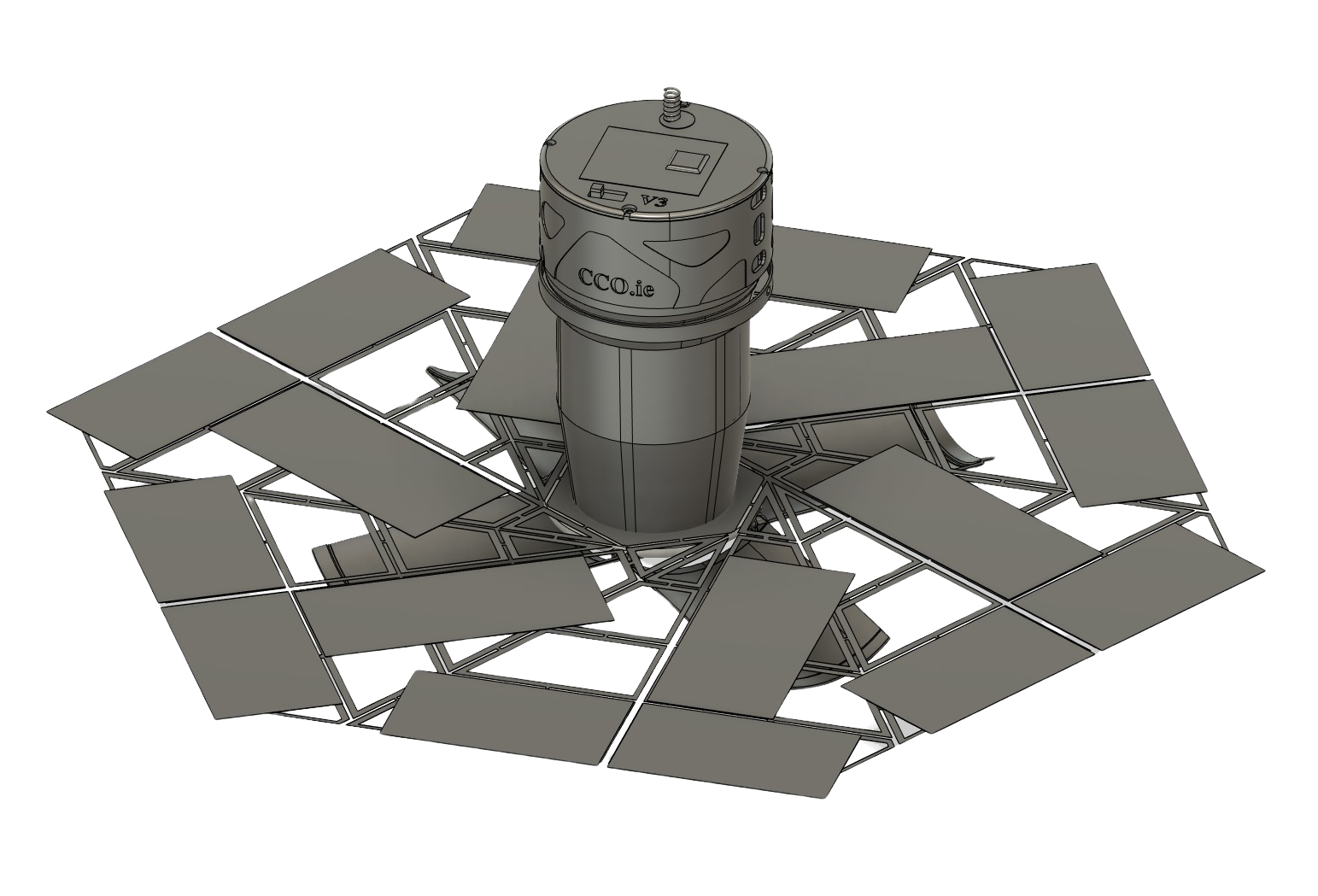

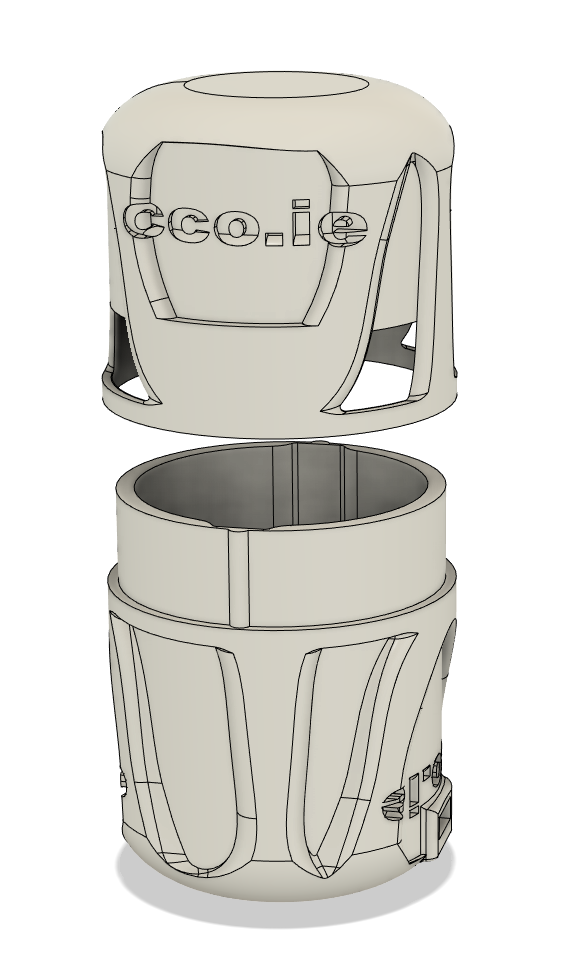

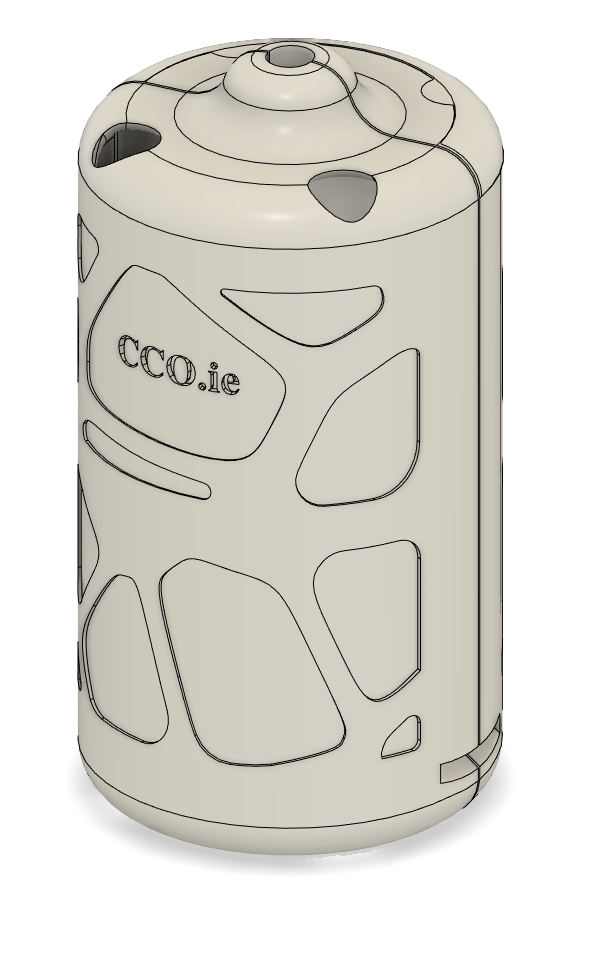

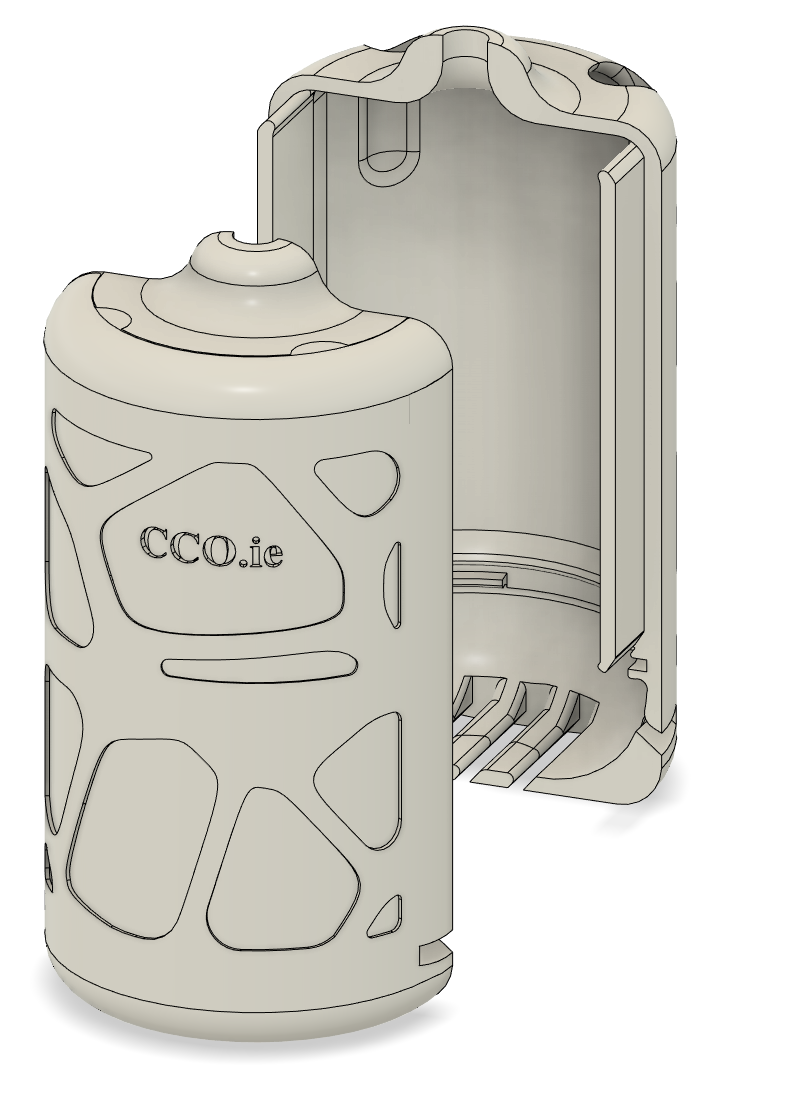

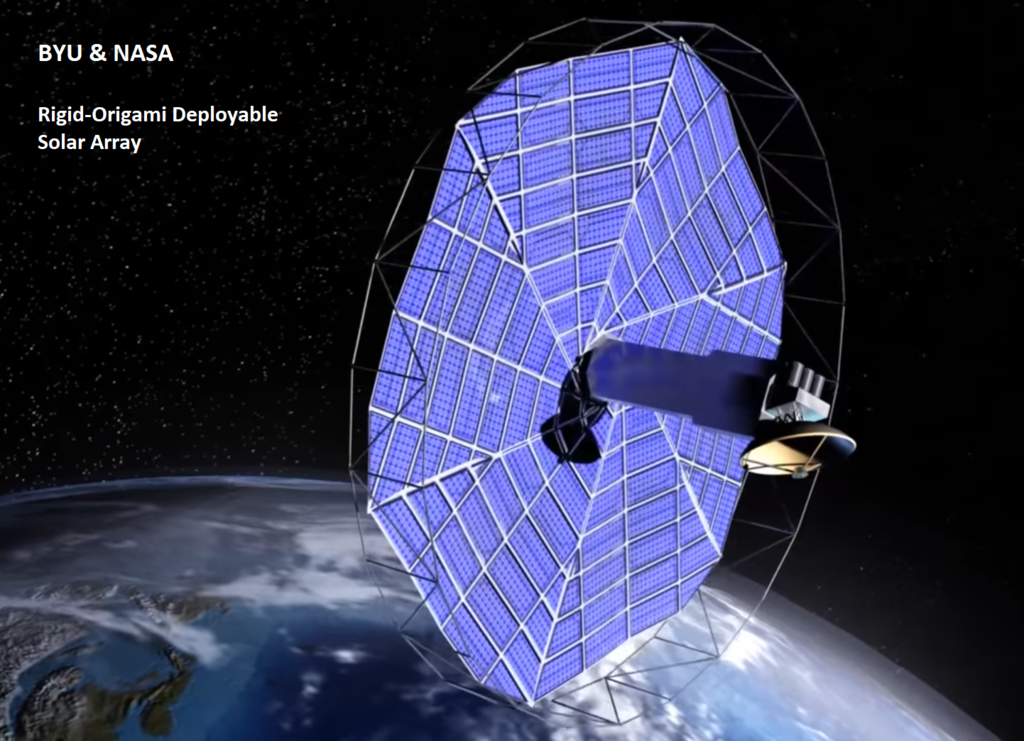

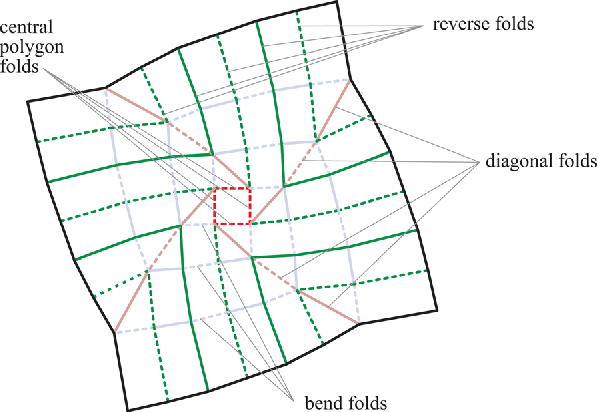

As head engineer of our school's Cansat Team, I led three can redesigns through regional, national, and representing Ireland at the European final. Our final design featured a 3D-printed titanium exterior, custom PCBs, and a rigid-origami folding solar array—held by four fairings, secured by a retainer-ring, attached to two parachute cords, and opened upon parachute deployment.

Challenges

The largest constraint I faced was space efficiency, which led to multiple redesigns. Our final design featured 1.5mm-thick titanium internal walls. However, this design choice contributed to some challenges on launch day:

- Weather conditions: The day had a UV index of 10 and temperatures reaching 40 degrees Celsius.

- Melted components: The extreme heat caused the PLA internal supporting structure for the electronics to melt.

- Electrical shorting: As a result of the melting, the power circuitry shorted against the titanium casing.

- Communication problems: We believe the titanium significantly affected our LoRa radio connection. When the rocket was carried facing away from us, the can lost connection, reconnecting only intermittently.

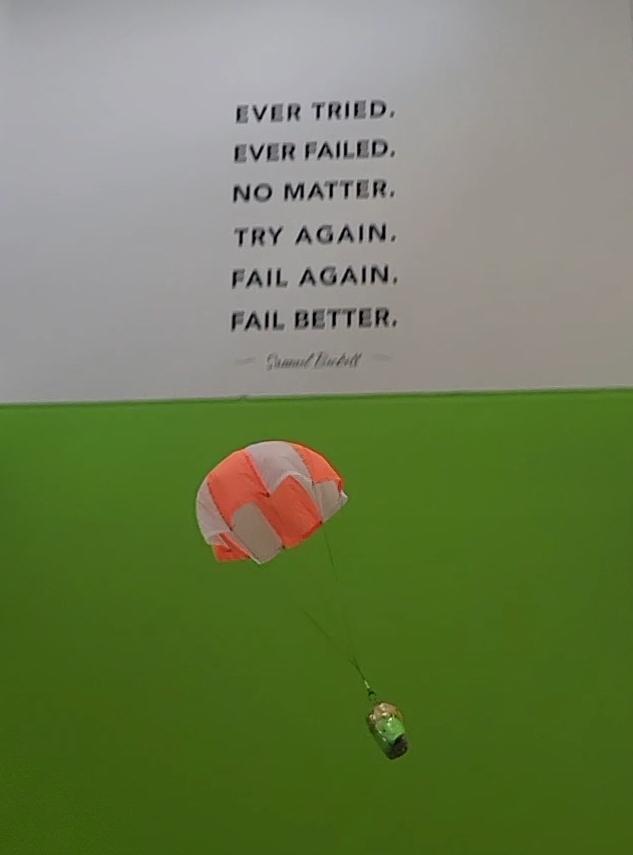

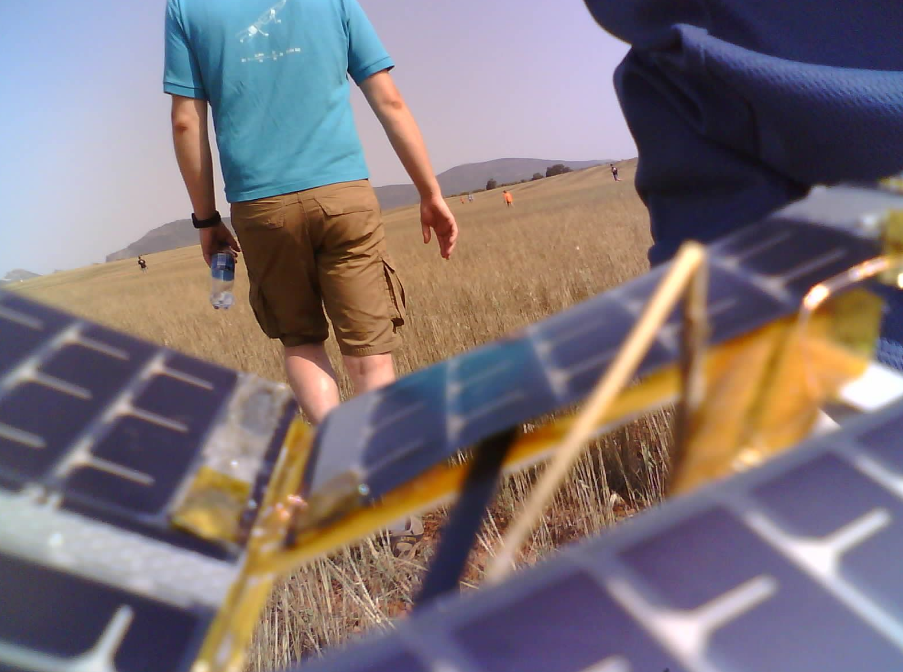

Despite these setbacks, our two onboard cameras successfully captured photographs during and after the launch. Additionally, our origami solar array deployed as expected!

Links and Resources

Solar Array Specifications

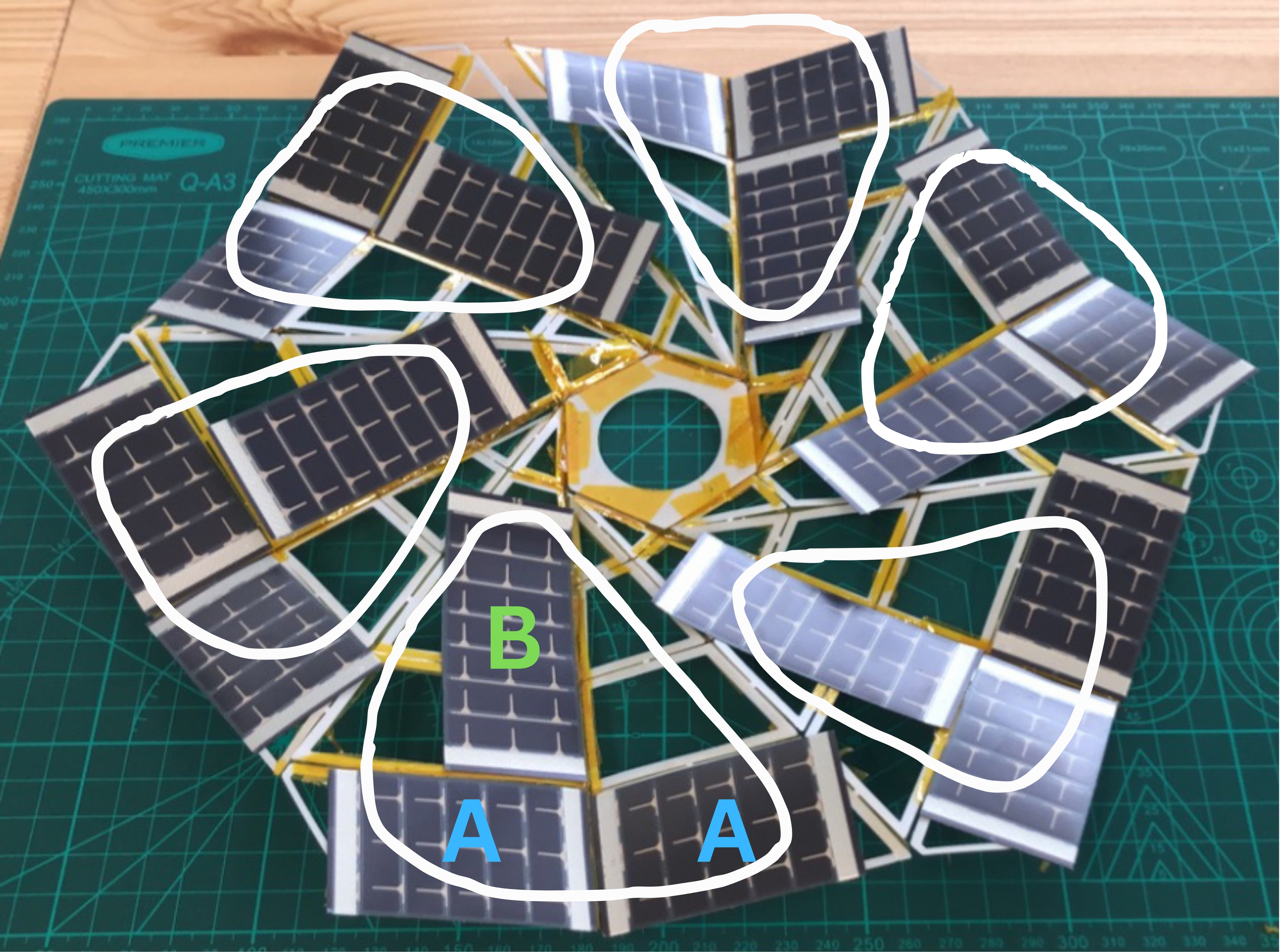

I constructed the frame of the array with 3d printed sections secured with Kapton tape and thread. Then I used repurposed spring steel from lanyards to aid the array in springing open upon deployment. To wire the cells I used enamelled copper wire. Annoyingly, these wires started to break after repeatedly testing the array deployment. If I were to do this again I would use conductive thread. In my initial testing there was huge variation in the performance of the PowerFilm cells out of the box, ~40% ended up being unusable. Thankfully, we had ordered enough.Total Surface Area: 470.64 cm²

Electrical Configuration: 6 groups of solar cells, each group consisting of two Type A and one Type B cell, arranged in series. Each group outputs 10.2V and 22mA. All 6 groups are wired in parallel, producing a final output of 10.2V at 132mA.

Total Power Output: 1,346.4mW (1.346W)

| Cell Type | Voltage | Current | Dimensions | Surface Area per Cell | Total Quantity | Total Surface Area |

|---|---|---|---|---|---|---|

| Type A | 3V | 22mA | 64mm x 37mm | 23.68 cm² | 12 | 284.16 cm² |

| Type B | 4.2V | 22mA | 84mm x 37mm | 31.08 cm² | 6 | 186.48 cm² |

| Final Array | 10.2V | 132mA | 18 cells total (12 Type A, 6 Type B) | 470.64 cm² | ||

2.jpg)